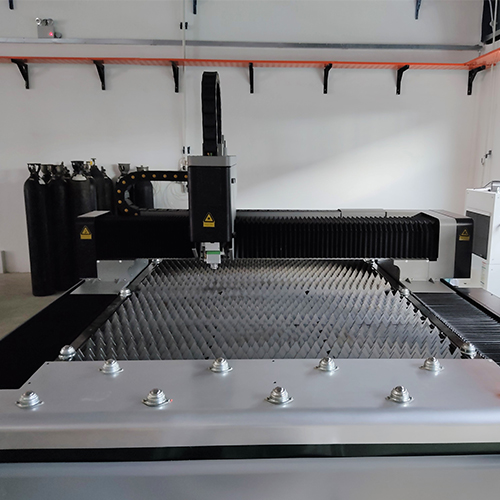

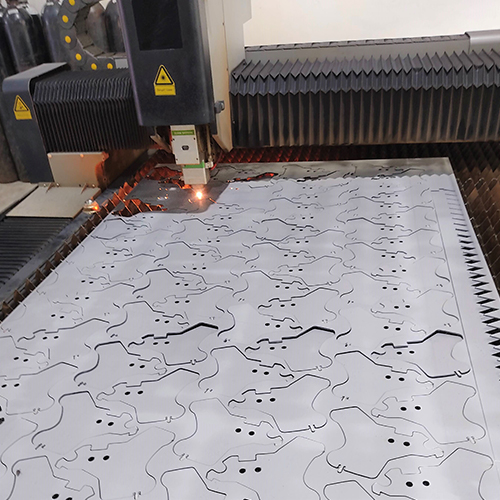

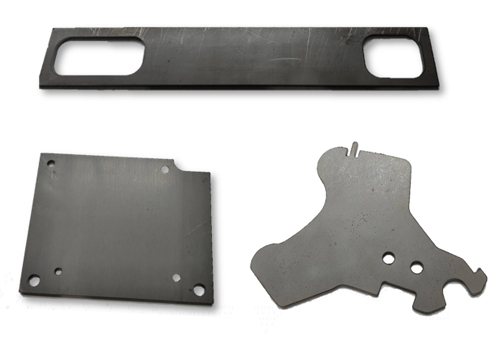

Laser Cut

Fiber laser cutting machine can carry up to 3000W laser power, a high-performance sheet metal laser cutting machine which is good at cutting metal and sheet metal effectively. This machine offer fast lead time and support low volume order. It also produce good surface finishing.

Cutting parts thickness up to :

- 18 mm for mild steel

- 8 mm for stainless steel

- 8 mm for aluminum

- 5 mm for brass

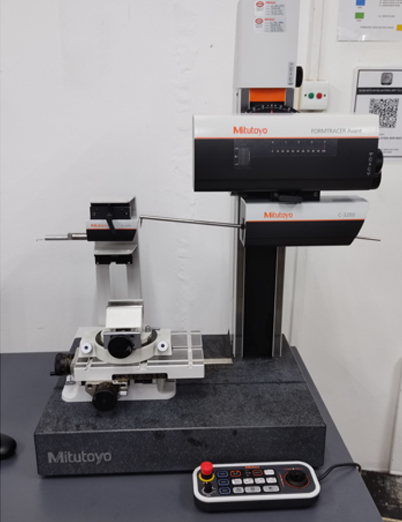

QUALITY ASSURANCE AND TEST FACILITIES

Our QA Department is equipped with a full range of inspection & test equipment, providing confidence that quality requirements will be fulfilled that ensures Bloxwich to deliver the best products and services possible.

Formtracer Contour

&

Surface Roughness Measuring Machine

Faro Portable CMM Measuring Arm

Tensile Tester

Digital Height Gauge

Microscope

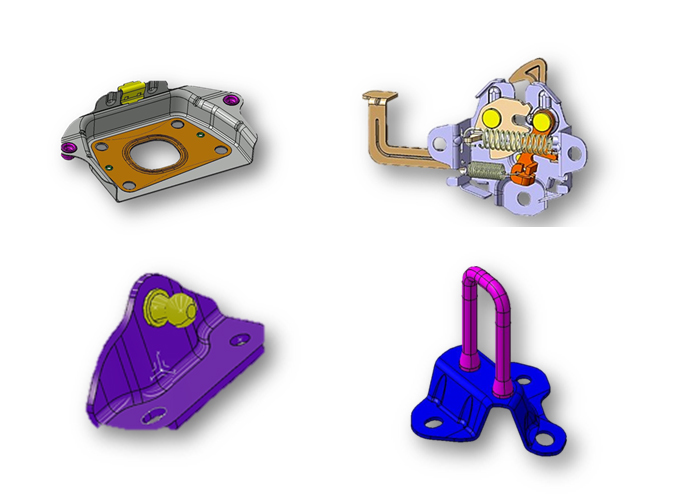

DESIGN CAPABILITIES – CATIA V5 R25

If 3D data is unavailable from customers at the start of a project we have the capability to create 3D solid models of component parts with our CATIA software from 2D drawings.

The 3D data is then used for the design & manufacture of metal stamping tools, pulley spinning tools, assembly jigs, welding jigs, & checking fixtures.

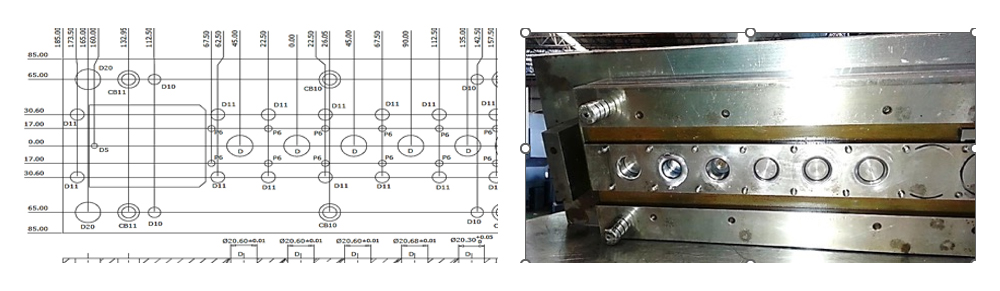

IN-HOUSE MANUFACTURING TOOLING

We provide a complete in-house tooling design and manufacturing service for all types of metal stamping tools including compound, progressive, draw, and prototype tooling to meet customer requirements.

Our high quality low cost tooling keeps production and

operation costs down, and we maintain all customer tooling at no cost whilst the part is in production.

- Fast tool modifications to accommodate engineering changes

- Tool design expertise

- Toolmakers who understand the pressroom

DEVELOPMENT – 3D LASER SCANNING

As part of our Faro portable CMM package, we also have 3D laser scanning facilities.

If customers are unable to provide 3D CAD data but have a sample part, we can scan the part geometry and then apply reverse engineering to design tooling and develop the manufacturing process.