METAL STAMPING FACILITIES

Tonnage range is from 110 to 260 tons. Components from a wide range of low & high tensile steels sourced mostly from Japanese, Korean & Taiwan mills.

Manufacture parts from hot rolled steel with tensile properties up to 590N/mm² and cold rolled steel up to 440N/mm² up to 6mm thickness.

Higher tensile materials are normally applied for body strengthening parts (B.I.W.) or safety critical items such as seating assemblies or body closures.

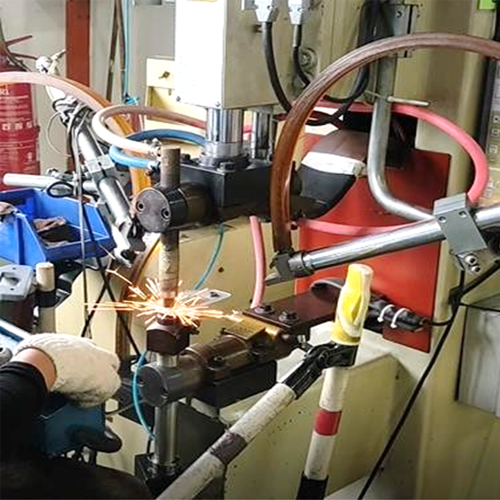

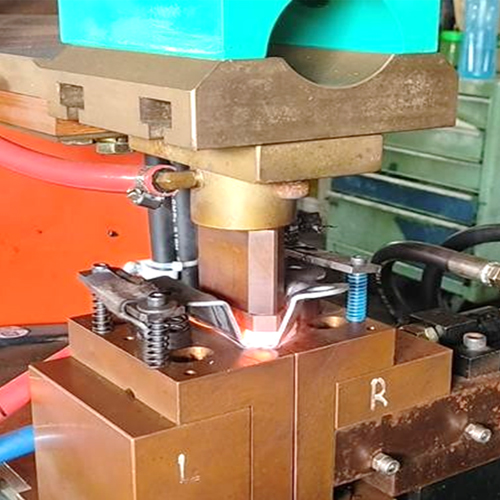

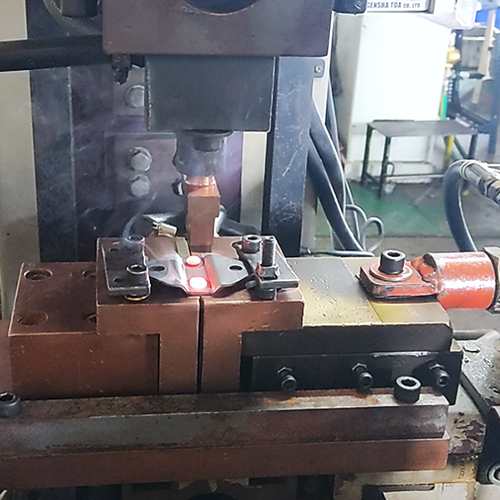

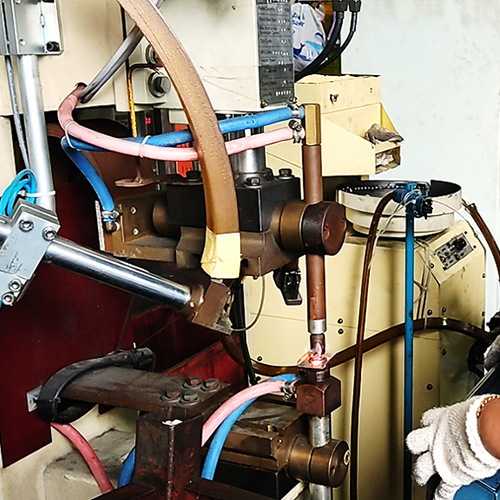

WELDING

Spotwelder

Hot Up Setting

Robotic Welding

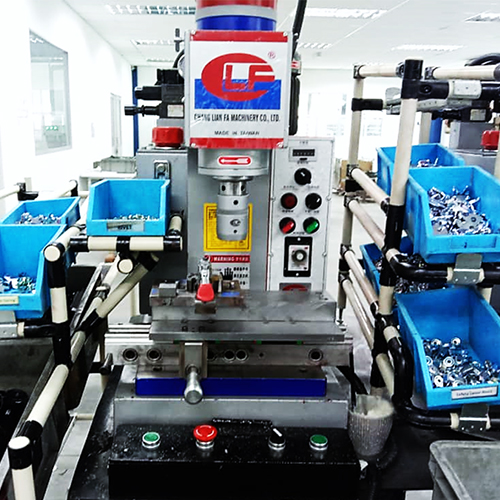

RIVETING

Rivet diameter capacity up to 12mm.

Current items in production are hood lock assemblies, seat bracket assemblies, damper mounting brackets & gasket turbocharger.

All safety critical items go through a final audit process where they are subject to a 100% functional test prior to dispatch.

Hydraulic Rivet

Pneumatic Rivet

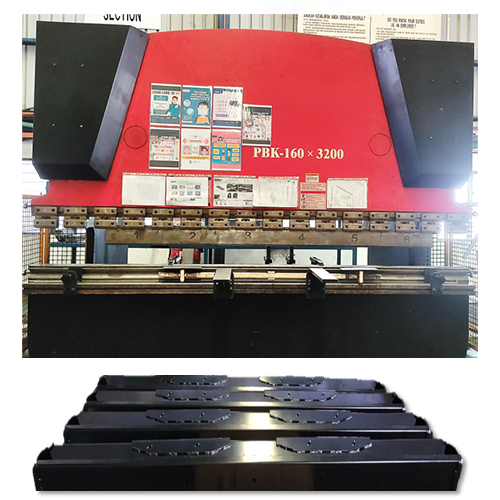

PRESS BRAKE BENDING

Machine capacity: - 160 tons

Maximum workpiece size: - 3,100 mm long x 8mm thick .

Tensile Strength: - 540N/mm²

Current parts in production are extension side member, chassis beams & bent brackets for Co2 welding into a larger assembly.

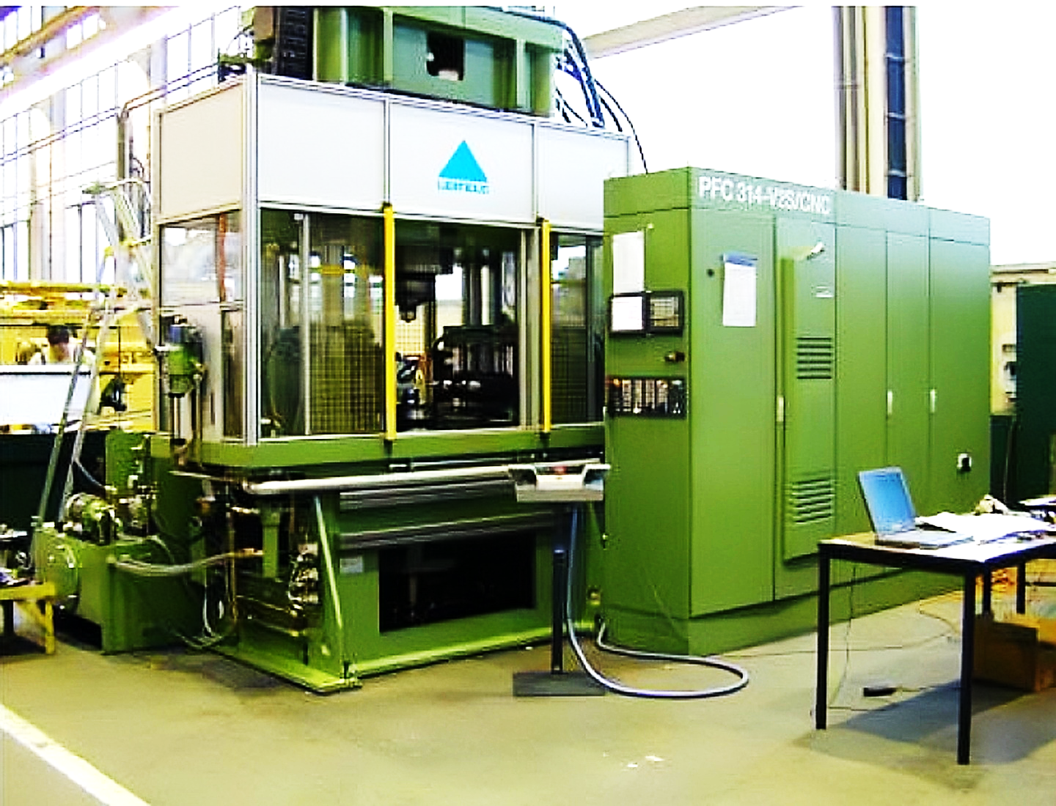

PULLEY SPINNING

Spun pulleys are the niche products of Bloxwich and have been in production for nearly 20 years.

We employ patented metal forming processes & technology developed by our machine supply partners, Leifeld Metal Spinning AG & WF Maschinenbau and Blechformtechnik GmbH & Co KG, in Germany.

We pride ourselves on our expertise in product design, tooling design & process development and being the only spun pulley manufacturer in Malaysia.

CNC MACHINES

A CNC lathe and CNC mill are two of the most important machines for custom fabrication and machining services.

CNC Lathe

A CNC lathe is ideal for conical or cylindrical pieces. A CNC lathe usually creates shapes, parts or objects that are mostly uniform across the conical or cylindrical surface, such as screws, shafts, knobs, disc cams, pin or crankshafts.

3 Axis Milling Center

CNC mill can work with more complex shapes. A CNC mill can create flat surfaces as needed, make deeper holes, and make pockets, planes, grooves, or edges. Example CF and Jigs.

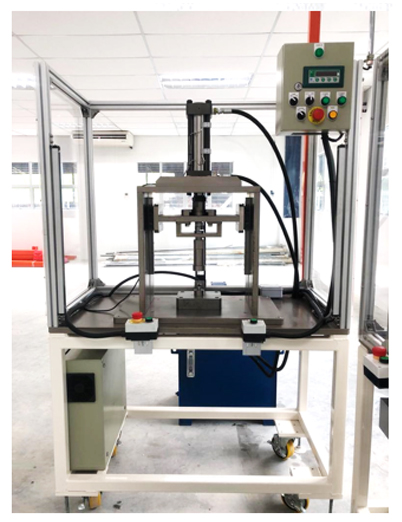

PRESS BEARING & FASTENING MACHINE

Press Bearing Machine

Fastening Machine